In today’s era of advanced automation, Brushless DC (BLDC) motors are revolutionizing the way machines operate. These motors are widely used in applications ranging from electric vehicles (EVs) and drones to home appliances and industrial automation systems due to their high efficiency, reliability, and low maintenance.

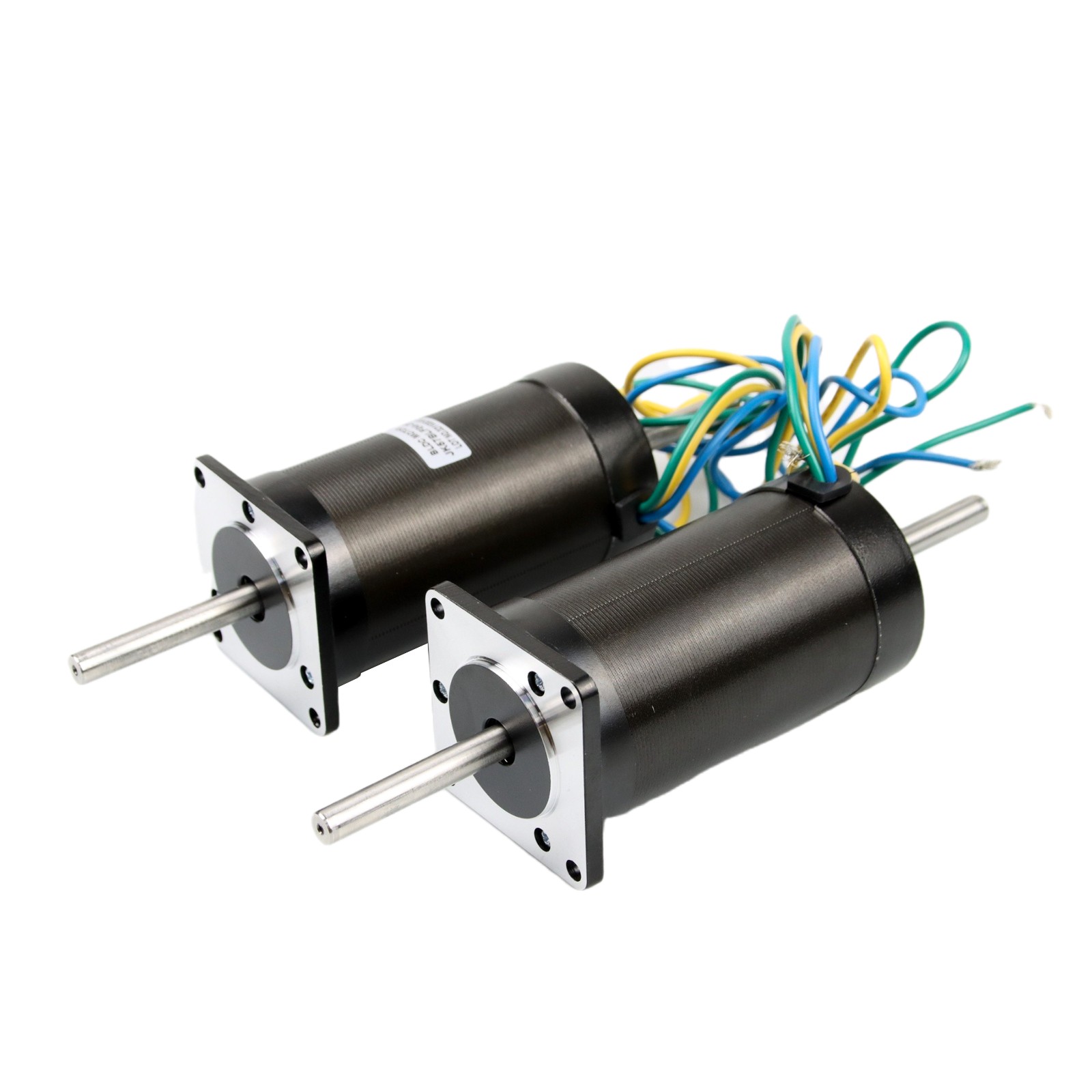

A Brushless DC Motor (BLDC Motor) is a type of permanent magnet synchronous motor that operates using direct current (DC) electricity but without the mechanical brushes and commutator found in traditional DC motors.

Instead of using brushes to switch the current in the motor windings, a BLDC motor uses an electronic controller to perform commutation—the process of directing current to the appropriate motor phase at the correct time.

Contains wound copper coils (electromagnets).

It’s the stationary part of the motor.

Connected to an external DC power source via an electronic controller.

Composed of permanent magnets.

It’s the rotating part of the motor.

The magnetic field interacts with the stator’s field to produce motion.

Acts like the "brain" of the motor.

Replaces traditional mechanical commutators.

Determines rotor position using sensors or algorithms and controls current flow to the stator accordingly.

Typically Hall Effect sensors.

Detect the position of the rotor to precisely time the switching of current in the stator.

The working of a BLDC Motor is based on the interaction of magnetic fields between the stator (electromagnets) and the rotor (permanent magnets). Here's a step-by-step overview:

The motor receives a DC voltage from a battery or power supply.

The controller receives feedback from position sensors or sensorless detection algorithms.

Based on rotor position, the controller sends current through specific stator windings, creating a rotating magnetic field.

The rotor aligns itself with the magnetic field and starts rotating. As the field rotates, the rotor follows continuously.

The controller switches current to different phases in the stator to maintain continuous rotation, achieving high-speed and efficient operation.

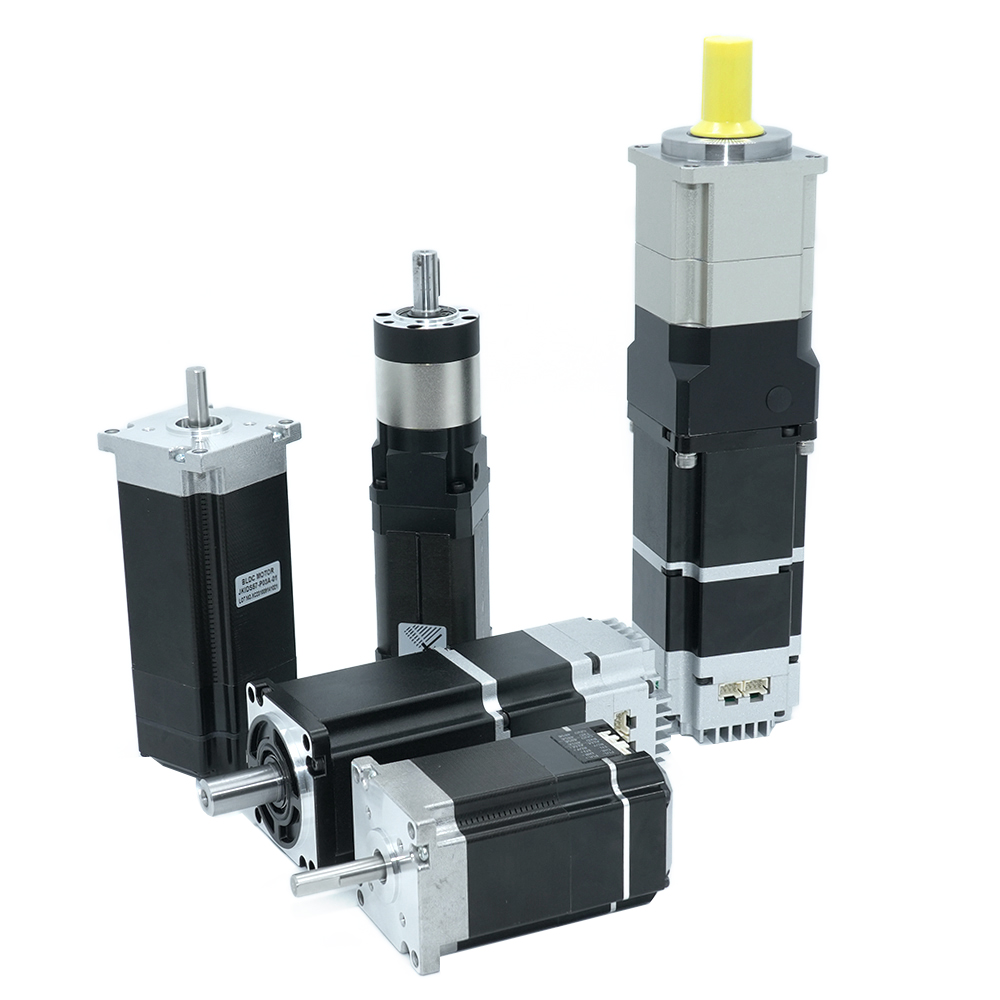

BLDC Motors can be categorized into different types based on rotor placement, control mechanism, and sensing technology.

|  |  | ||

| Standard Bldc Motors | Geared Bldc Motors | Integrated Bldc Motors | Brake Bldc Motors | Bldc Motor with Encoder |

| 33mm /42mm /57mm /60mm /80mm /86mm /110mm /130mm | Planetary Gearbox / Spur Gearbox / Worm Gearbox | Pulse / RS485 / Canopen | 33mm /42mm /57mm /60mm /80mm /86mm /110mm /130mm | Incremental Encoder / Absolute Encoder / Optical Encoder / Magnetic Encoder |

|  |  |  | |

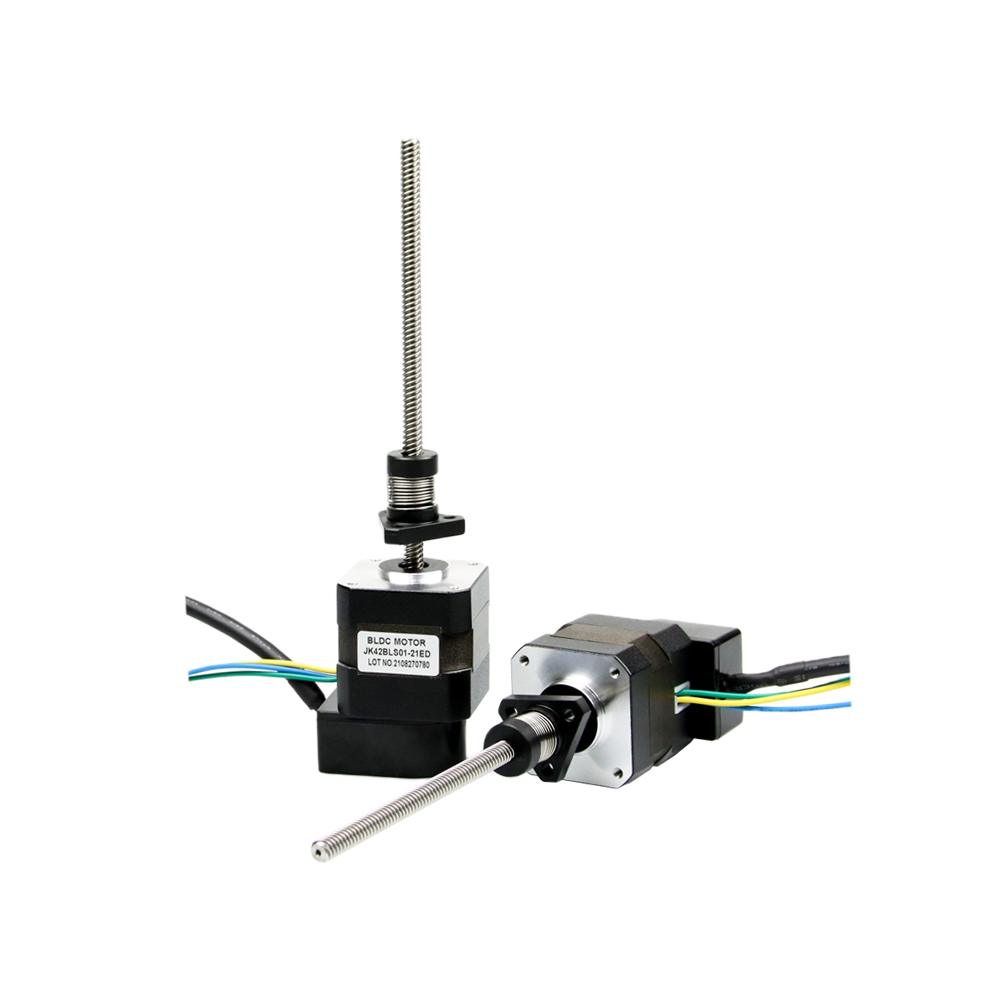

| Linear Bldc Motors | IP65 Waterproof Bldc Motors | Out Runner Bldc Motors | Coreless Dc Motors | Dual Shaft Bldc Motors |

| External T-type / Ball Screw / Non-captive lead screw | IP30 / IP54 / IP65 / IP67 Waterproof and dustyproof | 24V / 30-70W Power | Gearbox / encoder / Lead Screw... | Customized |

if you need customized Bldc Motors, please contact us.

In inner rotor motors, the rotor is placed inside the stator. These are the most common type of BLDC motors and are widely used in industries and appliances.

Rotor rotates at the center

Stator surrounds the rotor

Better heat dissipation as the stator is fixed

Power tools

Industrial robots

Electric bicycles

Cooling fans

Also known as outrunners, these motors have the rotor outside the stator. The outer casing rotates, while the coils remain fixed inside.

Higher torque at lower RPM

Compact and energy-efficient

Limited in high-speed applications

Ceiling fans

Drone motors

Compact electric vehicles

Small home appliances

These BLDC Motors use position sensors (typically Hall Effect sensors) to determine rotor position. The controller uses this information for accurate commutation.

Precise control over speed and position

Ideal for variable load conditions

Smooth starting and stopping

CNC machinery

Robotics

Medical equipment

Electric scooters

In this type, rotor position is estimated through back EMF (electromotive force) instead of physical sensors.

Cheaper and more compact

Less complex wiring

Slightly harder to start under load

Drones and UAVs

Fans and blowers

EV pumps and compressors

Battery-operated devices

These BLDC Motors have a trapezoidal back EMF waveform, meaning the voltage induced in the stator windings has a flat-top shape. Commutation is typically six-step.

Simple drive electronics

High efficiency

Lower cost compared to sinusoidal types

Pumps and blowers

E-bikes and scooters

Sinusoidal BLDC Motors generate a smooth, sine wave-shaped back EMF, allowing for quiet and vibration-free performance.

Smoother torque production

Better for precision motion control

More complex drive systems

Precision robotics

Medical devices

High-end HVAC systems

3D printers

Frameless BLDC Motors are provided without housing or bearings, allowing for integration into customized mechanical structures.

Lightweight and compact

High torque-to-weight ratio

Ideal for direct-drive applications

Aerospace

Cobots (collaborative robots)

Surgical robots

Direct drive mechanisms

As India accelerates towards an electrified and automated future, Brushless DC (BLDC) motors are becoming increasingly vital across sectors—from electric vehicles (EVs) to home appliances, robotics, and industrial automation. Known for their high efficiency, compact design, and low maintenance, BLDC motors are a core component in the country’s transition to smart manufacturing and sustainable mobility.

Here is a comprehensive list of the Top 20 BLDC Motor manufacturers in India, along with their company profiles, key products, and unique advantages that set them apart.

Founded in 1946, Bharat Bijlee is a BLDC Motor manufacturer in electric motors and drives, with strong R&D and manufacturing capabilities.

BLDC motors for HVAC and industrial automation

Compact BLDC drive systems

Robust design for heavy-duty applications

Energy-efficient operation

Proven track record in OEM solutions

Part of the Murugappa Group, CG Power is a trusted BLDC Motor manufacturer in electrical engineering, offering a range of motion control products.

Industrial-grade BLDC motors

Customized BLDC motors for fans and pumps

ISO-certified quality

Nationwide service and support

Advanced thermal management

A key BLDC Motor manufacturer in motion control systems, Rotomag specializes in DC motors for renewable energy and industrial use.

BLDC motors for solar pumps

Low-voltage BLDC motors

Focus on green energy applications

Long life and reliable performance

Easy integration into solar systems

A BLDC Motor manufacturer of the Japanese giant Nidec Corporation, it brings global expertise in motor design to Indian markets.

Automotive-grade BLDC motors

High-efficiency HVAC BLDC systems

Ultra-compact and powerful

Silent operation

Ideal for EV and appliance sectors

A global BLDC Motor manufacturer in precision motion control, Allied Motion India delivers tailored motor solutions across verticals.

Custom BLDC motors for medical and defense

Servo-BLDC hybrid systems

High torque density

Superior build quality

Advanced thermal and EMI shielding

With decades of expertise in motion solutions, Emco is a leading BLDC Motor manufacturer and offers tailored BLDC solutions for OEMs and machine builders.

BLDC motors for automation and robotics

Controllers and matched drive systems

Compact design

Easy field programmability

Smooth torque delivery

A Pune-based BLDC Motor manufacturer specializing in smart sensor systems and motion control for aerospace and industrial automation.

BLDC motors for drones and UAVs

Miniature precision BLDC motors

Aerospace-grade reliability

Lightweight and efficient

High RPM and control accuracy

ElectroCraft is a global BLDC Motor manufacturer to India, serving sectors such as robotics, automation, and medical devices.

Axial flux BLDC motors

Compact torque-optimized motors

Quiet operation

Highly customizable

Excellent torque-speed profile

A BLDC Motor manufacturer and known for R&D-driven motor design, Trident Techlabs develops high-precision motors for electric mobility and embedded systems.

EV-grade BLDC motors

Low-voltage controllers

Designed for Indian conditions

Cost-effective EV solutions

Long lifecycle with minimal maintenance

Part of the global Johnson Electric Group, the company is a trusted BLDC Motor manufacturer of precision motors for global OEMs.

BLDC motors for home appliances

Automotive BLDC motors

High energy efficiency

Proven reliability

Global standards of performance

Based in Gujarat, Precise Motors is a leading BLDC Motor manufacturer and known for high-performance motor manufacturing with a focus on automation.

BLDC motors for conveyors and fans

Integrated BLDC motor controllers

Fast response time

Compact size

High reliability under continuous operation

Servokon, a renowned electrical BLDC Motor manufacturer, has entered the BLDC motor space with innovative offerings.

BLDC ceiling fan motors

BLDC drives for HVAC systems

Energy star certified

Noiseless operation

Ideal for Indian climate conditions

A joint venture between Toshiba and Mitsubishi, TMEIC is a leading BLDC Motor manufacturer and brings Japanese precision into industrial motor systems.

BLDC motors for automation and smart manufacturing

Industrial servo-integrated BLDC solutions

Field-proven durability

Compatible with IIoT platforms

Scalable for heavy-duty use

An emerging BLDC Motor manufacturer in the EV motor domain, Omak designs innovative BLDC motors for two-wheelers and industrial use.

Mid-drive BLDC motors for e-bikes

Hub BLDC motors for e-rickshaws

Cost-effective and reliable

Indian terrain-tested

High efficiency and smooth ride experience

A top EMS (Electronic Manufacturing Services) BLDC Motor manufacturer, Elin manufactures BLDC motors for major appliance brands.

BLDC fan and mixer motors

Appliance-grade compact motors

Bulk production capability

High-quality assurance

Ideal for domestic appliance manufacturers

Focused exclusively on brushless motor technologies, BMS India is a leading BLDC Motor manufacturer and offers R&D-heavy, customized BLDC solutions.

High-torque BLDC motors

Sensorless and sensored variants

R&D driven designs

Wide voltage support

Low heat generation

Micromot is a leading BLDC Motor manufacturer and specializes in motion control systems and power electronics, offering BLDC drives for OEM integrations.

Smart BLDC controllers

Integrated BLDC motor-drive units

Plug-and-play options

Reliable field performance

Multi-protocol communication

An emerging BLDC Motor manufacturer catering to small EV and agricultural applications with rugged BLDC motor systems.

Agricultural sprayer BLDC motors

Electric mobility motor kits

Designed for rural applications

IP65 rated enclosures

Long battery life support

Jkongmotor focused BLDC Motor manufacturer offering robust electric drive solutions with a specialization in high-efficiency BLDC motors.

Drive systems for electric 3-wheelers

Modular BLDC motors for scooters

High efficiency with minimal losses

Excellent hill-climb torque

Compatible with regenerative braking

A domestic BLDC Motor manufacturer known for rugged motor solutions tailored for Indian industrial environments.

BLDC motors for machine tools and elevators

Customized controller-motor kits

Locally sourced materials

Affordable maintenance

Easily serviceable design

Minimal energy losses due to the absence of brushes and friction.

Converts more electrical energy into mechanical motion.

No brush wear means less frequent maintenance and longer operational life.

Delivers excellent torque-to-weight ratio.

Capable of high RPM operations with stable performance.

Reduced mechanical noise compared to brushed motors.

Ideal for appliances, medical equipment, and precision devices.

Fine-tuned speed, torque, and direction control using feedback loops.

Essential for automation, robotics, and EVs.

BLDC Motors are found in a wide range of modern technologies:

Electric Vehicles (e-bikes, scooters, cars)

Drones and UAVs

CNC and Industrial Automation

Home Appliances (fans, air conditioners, washing machines)

Robotics and 3D Printers

Medical Devices (CPAP machines, ventilators)

HVAC and Pumps

| Feature | Brushed Motor | BLDC Motor |

|---|---|---|

| Efficiency | Moderate | High |

| Maintenance | Frequent (brushes) | Minimal |

| Lifespan | Shorter | Longer |

| Noise Level | Higher | Quieter |

| Speed Control | Limited | Precise |

| Cost | Cheaper upfront | Better ROI long-term |

A BLDC Motor is a high-performance, energy-efficient, and low-maintenance alternative to traditional brushed motors. Its versatility and precision make it a critical component in modern applications, especially where efficiency, reliability, and speed control are essential.

With the rising demand in electric mobility, smart homes, and industrial automation, BLDC motors are becoming the future of motion control across the globe.

The type of BLDC Motor you choose depends entirely on your application, load characteristics, and performance expectations. Whether you need high-speed rotation for tools or silent operation for medical devices, there’s a BLDC motor built precisely for that job.

Understanding these different types helps engineers and product designers make informed decisions that optimize performance, cost, and reliability.

India is emerging as a hub for BLDC motor manufacturing, driven by local innovation, government support for EVs, and a thriving automation market. From small startups to global giants, these manufacturers are delivering motors that combine efficiency, performance, and adaptability to meet India's growing industrial and mobility demands.

View More(Total0)Comment Lists