A planetary gearbox is a type of gear system that uses a central sun gear, multiple planet gears, and an outer ring gear to transmit power. The planetary gears rotate around the sun gear and mesh with the ring gear, allowing for high torque transmission, compact size, and high efficiency. It’s commonly used in applications requiring precise motion control and durable performance.

Planetary gearboxes are celebrated for their ability to handle high torque loads, achieved through the distribution of forces across multiple planetary gears, which boosts stability and ensures longer service life. They are highly efficient, with low energy losses, reaching up to 98% efficiency in their initial stage.

Thanks to their compact structure, these gearboxes deliver a high power density, outperforming other gear types in this regard. The external ring gear design further minimizes the overall volume and weight of the system.

Jkongmotor has over 15 years of experience in producing stepper motors and brushless DC motors. Additionally, we offer worm gearboxes, planetary gearboxes, brakes, encoders, drivers, integrated servo motors, and other motor-driven components. Feel free to contact us for inquiries.

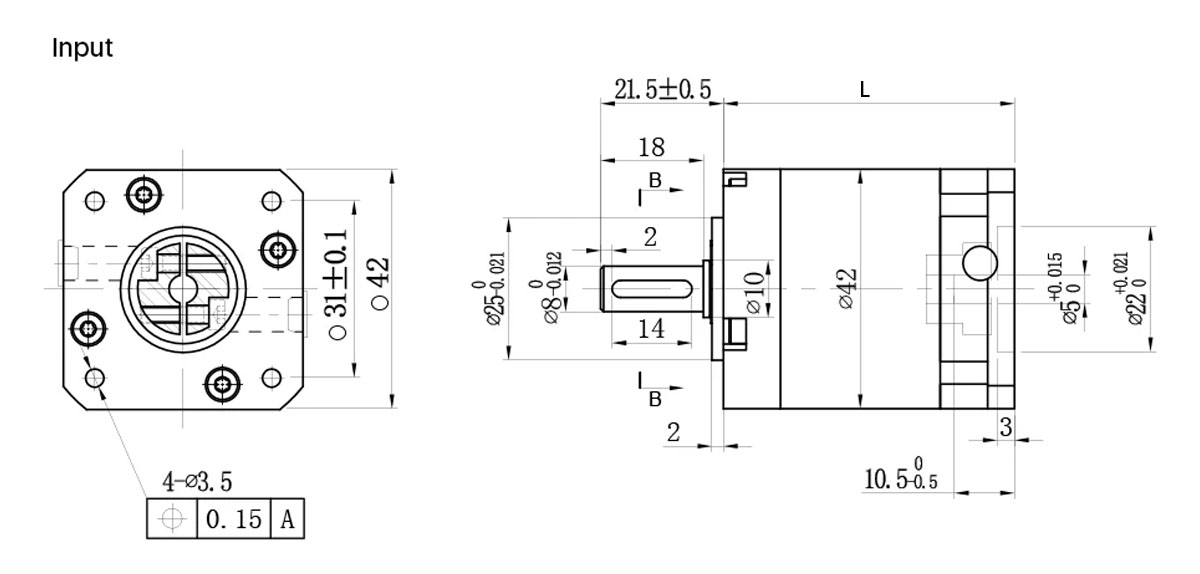

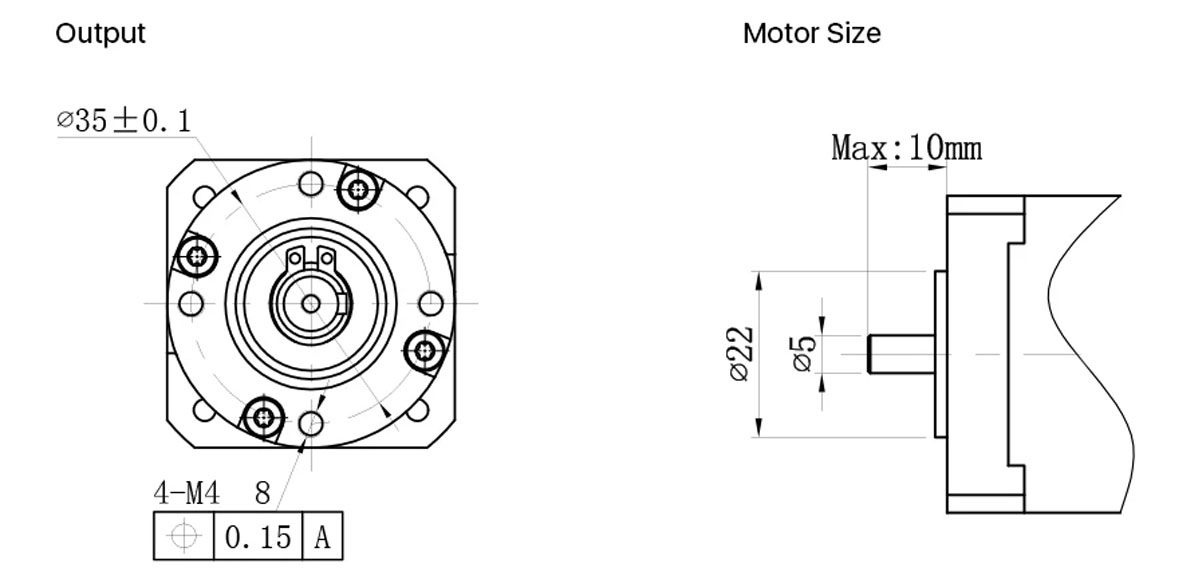

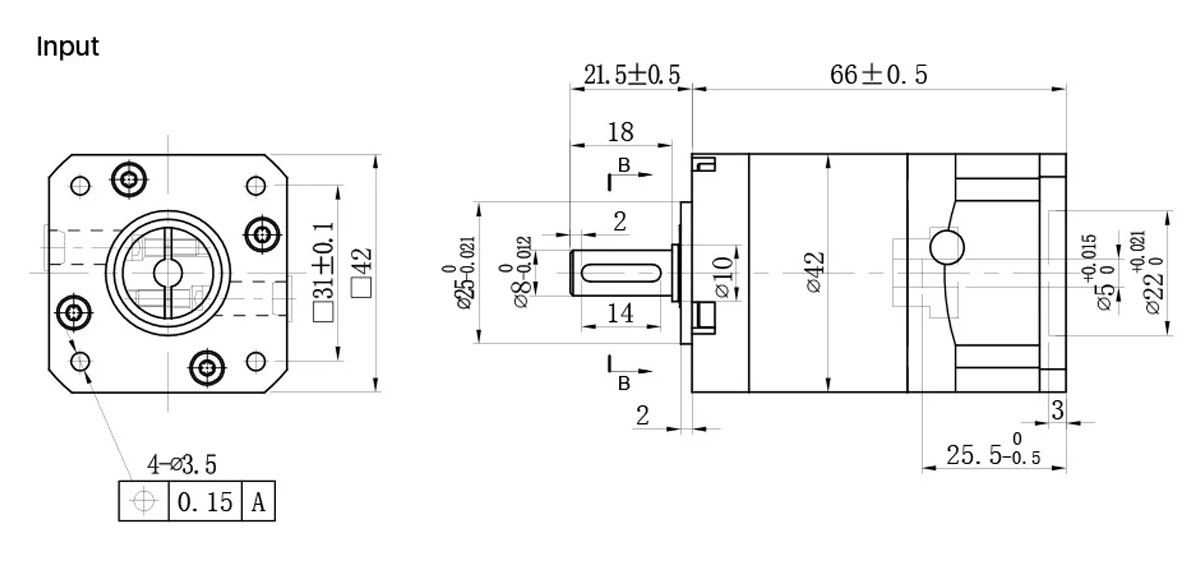

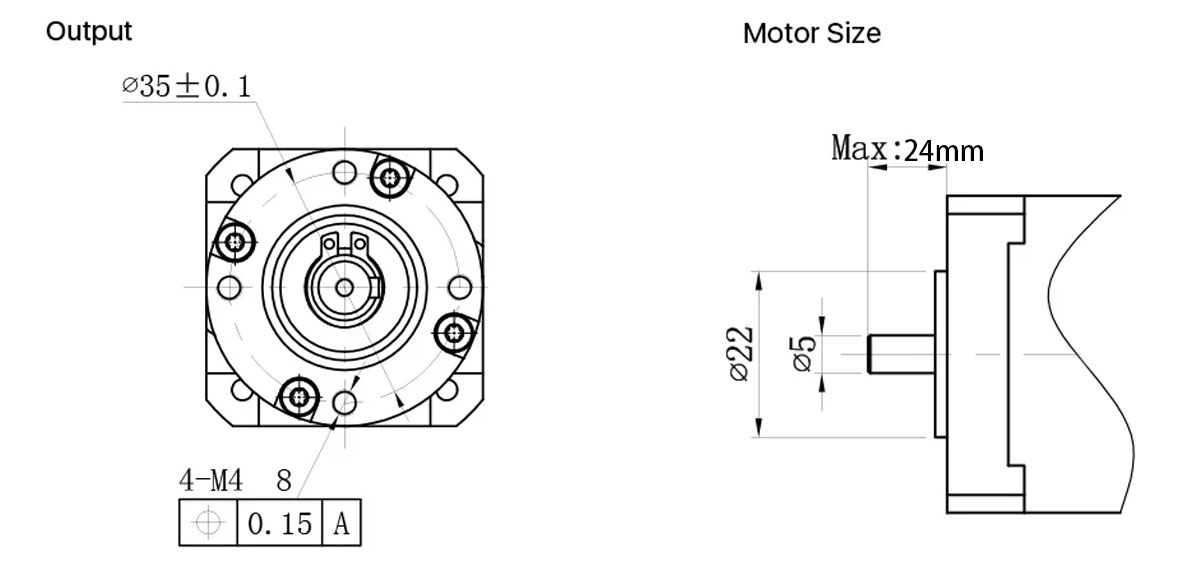

Product Type: HPR42 Nema 17 Planetary Gearbox

Suitable Motor:Nema 17 42mm stepper motor or bldc motor

Feature summary:Low Inertia、Low Noise、High Torque

Place of Origin:china

Minimum order quantity:10pcs

Material Science:stator, rotor, stainless steel shaft, copper wire, magnetic steel...

Applicatin Scope: 42mm Nema 17 stepping motor or brushless dc motor

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

| Model | / | JK-HPR42-L1 | JK-HPR42-L2 | |||||||||||||||

| Gear Ratio | / | 3 | 4 | 5 | 7 | 10 | 15 | 16 | 20 | 25 | 28 | 30 | 35 | 40 | 45 | 50 | 70 | 100 |

| Gear Trains | / | 1 | 2 | |||||||||||||||

| Gearbox Length | mm | 61.5 | 72.5 | |||||||||||||||

| Rated Torque | N.m | 8 | 9 | 9 | 5 | 5 | 10 | 12 | 12 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 5 |

| Sundden Stop Torque | N.m | 16 | 18 | 18 | 10 | 10 | 20 | 24 | 24 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 10 |

| Back Lash | arcmin | ≤15 arcmin | ≤20 arcmin | |||||||||||||||

| Efficiency | % | 96 | 94 | |||||||||||||||

| Suitable Motor Dimension | mm | Φ5-10 / Φ22-2 / F31-M3 | Φ5-10 / Φ22-2 / F31-M3 | |||||||||||||||

| Rated Input Speed | Rpm | 3000 | 3000 | |||||||||||||||

| Max Input Speed | Rpm | 6000 | 6000 | |||||||||||||||

| Average Life Span | h | 20000 | 20000 | |||||||||||||||

| Axial Force | N | 100 | 100 | |||||||||||||||

| Radial Force | N | 300 | 300 | |||||||||||||||

| Noise | dB | ≤55 | ≤65 | |||||||||||||||

| Protection Level | IP | IP54 | IP54 | |||||||||||||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | |||||||||||||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | |||||||||||||||

| Model | / | JK-HPR42-L1SW | JK-HPR42-L2SW | ||||||||||||||

| Gear Ratio | / | 3 | 4 | 5 | 7 | 10 | 15 | 16 | 20 | 25 | 28 | 30 | 35 | 40 | 50 | 70 | 100 |

| Gear Trains | / | 1 | 2 | ||||||||||||||

| Gearbox Length | mm | 76.5 | 87.5 | ||||||||||||||

| Rated Torque | N.m | 8 | 9 | 9 | 5 | 5 | 10 | 12 | 12 | 10 | 10 | 12 | 10 | 10 | 10 | 10 | 5 |

| Sundden Stop Torque | N.m | 16 | 18 | 18 | 10 | 10 | 20 | 24 | 24 | 20 | 20 | 24 | 20 | 20 | 20 | 20 | 10 |

| Back Lash | arcmin | ≤15 arcmin | ≤20 arcmin | ||||||||||||||

| Efficiency | % | 96 | 94 | ||||||||||||||

| Suitable Motor Dimension | mm | Φ5-24 / Φ22-2 / F31-M3 | Φ5-24 / Φ22-2 / F31-M3 | ||||||||||||||

| Rated Input Speed | Rpm | 3000 | 3000 | ||||||||||||||

| Max Input Speed | Rpm | 6000 | 6000 | ||||||||||||||

| Average Life Span | h | 20000 | 20000 | ||||||||||||||

| Axial Force | N | 100 | 100 | ||||||||||||||

| Radial Force | N | 300 | 300 | ||||||||||||||

| Noise | dB | ≤65 | ≤65 | ||||||||||||||

| Protection Level | IP | IP54 | IP54 | ||||||||||||||

| Work Temp. | ℃ | -20 to +150 | -20 to +150 | ||||||||||||||

| Out Shaft Type | / | Key Shaft Type | Key Shaft Type | ||||||||||||||

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| JK42HS25-0404 | 1.8 | 25 | 0.4 | 24 | 36 | 1.8 | 4 | 75 | 20 | 0.15 |

| JK42HS28-0504 | 1.8 | 28 | 0.5 | 20 | 21 | 1.5 | 4 | 85 | 24 | 0.22 |

| JK42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.2 | 4 | 120 | 34 | 0.22 |

| JK42HS34-0406 | 1.8 | 34 | 0.4 | 24 | 15 | 1.6 | 6 | 120 | 34 | 0.22 |

| JK42HS34-0956 | 1.8 | 34 | 0.95 | 4.2 | 2.5 | 1.6 | 6 | 120 | 34 | 0.22 |

| JK42HS40-0406 | 1.8 | 40 | 0.4 | 30 | 30 | 2.6 | 6 | 150 | 54 | 0.28 |

| JK42HS40-1684 | 1.8 | 40 | 1.68 | 1.65 | 3.2 | 3.6 | 4 | 150 | 54 | 0.28 |

| JK42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 2.9 | 6 | 150 | 54 | 0.28 |

| JK42HS48-0406 | 1.8 | 48 | 0.4 | 30 | 25 | 3.1 | 6 | 260 | 68 | 0.35 |

| JK42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 4.4 | 4 | 260 | 68 | 0.35 |

| JK42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 3.17 | 6 | 260 | 68 | 0.35 |

| JK42HS60-0406 | 1.8 | 60 | 0.4 | 30 | 39 | 6.5 | 6 | 280 | 102 | 0.5 |

| JK42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.5 |

| JK42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.5 |

| JK42HM34-1334 | 0.9 | 34 | 1.33 | 2.1 | 4.2 | 2.2 | 4 | 200 | 35 | 0.22 |

| JK42HM34-0316 | 0.9 | 34 | 0.31 | 38.5 | 33 | 1.58 | 6 | 200 | 35 | 0.22 |

| JK42HM34-0956 | 0.9 | 34 | 0.95 | 4.2 | 4 | 1.58 | 6 | 200 | 35 | 0.22 |

| JK42HM40-1684 | 0.9 | 40 | 1.68 | 1.65 | 3.2 | 3.3 | 4 | 220 | 54 | 0.28 |

| JK42HM40-0406 | 0.9 | 40 | 0.4 | 30 | 30 | 2.59 | 6 | 220 | 54 | 0.28 |

| JK42HM40-1206 | 0.9 | 40 | 1.2 | 3.3 | 3.4 | 2.59 | 6 | 220 | 54 | 0.28 |

| JK42HM48-1684 | 0.9 | 48 | 1.68 | 1.65 | 4.1 | 4.4 | 4 | 250 | 68 | 0.35 |

| JK42HM48-1206 | 0.9 | 48 | 1.2 | 3.3 | 4 | 3.17 | 6 | 250 | 68 | 0.35 |

| JK42HM48-0406 | 0.9 | 48 | 0.4 | 30 | 38 | 3.17 | 6 | 250 | 68 | 0.35 |

| JK42HM60-1684 | 0.9 | 60 | 1.68 | 1.65 | 5 | 5.5 | 4 | 270 | 106 | 0.55 |

Note: Above only for representative products, products of special request can be made according to the customer request.

| Specification | Unit | Model | |||

| JK42BLS01 | JK42BLS02 | JK42BLS03 | JK42BLS04 | ||

| Phase | 3 | ||||

| Number Of Poles | Poles | 8 | |||

| Rated Voltage | VDC | 24 | |||

| Rated Speed | Rpm | 4000 | |||

| Rated Torque | N.m | 0.0625 | 0.125 | 0.185 | 0.25 |

| Peak Current | Amps | 1.8 | 3.3 | 4.8 | 6.3 |

| Rated Power | W | 26 | 52.5 | 77.5 | 105 |

| Peak Torque | N.m | 0.19 | 0.38 | 0.56 | 0.75 |

| Peak Current | Amps | 5.4 | 10.6 | 15.5 | 20 |

| Back E.M.F | V/Krpm | 4.1 | 4.2 | 4.3 | 4.3 |

| Torque Constant | N.m/A | 0.039 | 0.04 | 0.041 | 0.041 |

| Rotor Inertia | g.cm2 | 24 | 48 | 72 | 96 |

| Body Length | mm | 41 | 61 | 81 | 100 |

| Weight | Kg | 0.3 | 0.45 | 0.65 | 0.8 |

| Sensor | Honeywell | ||||

| Insulation Class | B | ||||

| Degree of Protection | IP30 | ||||

| Storage Temperature | -25~+70℃ | ||||

| Operating Temperature | -15~+50℃ | ||||

| Working Humidity | 85% RH or below (no condensation) | ||||

| Working Environment | Outdoor (no direct sunlight), no corrosive gas, no flammable gas, no oil mist, no dust | ||||

| Altitude | 1000 meters or less | ||||

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.